In the article “How to identify a transformer or a capacitor that has PCB?“ we said that the only way to know if a transformer with dielectric mineral oil contains PCB, was through an analysis. But what are the types of analysis that can be done, and what does the choice of one method or another depend on? In this article we will tell you which analysis we use in Trédi Argentina and what are the advantages and disadvantages of each type of test.

Knowing the PCB content in the oil of a transformer is fundamental to make an inventory of the electrical equipment, according to the regulations established by each environmental authority. But it is also essential for choosing the type of treatment to be carried out.

Depending on the degree of accuracy, we can divide the analyses into three groups:

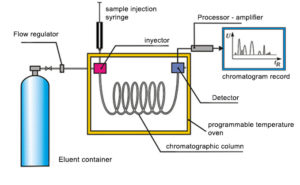

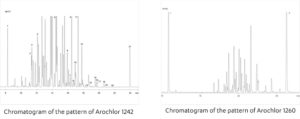

Gas chromatography is a technique used to separate volatile compounds from a sample. The mobile phase is an inert gas (nitrogen or helium) that transports the volatilized sample in the injector, through the chromatographic column. The different compounds are separated according to their degree of volatility (boiling point, molecular weight) and their affinity for the stationary phase. Among the most commonly used detectors is the ECD (electron capture detector). This detector is very selective and sensitive to the presence of molecules containing halogens, mainly chlorine, such as polychlorinated biphenyls or some pesticides.

In Argentina we use the ASTM 4059-00 “Standard Test Method for Analysis of Polychlorinated Biphenyls in Insulating Liquids by Gas Chromatography”.

The Chloride Analyzer is an easy-to-use option for on-site analysis of PCBs and other chlorinated organic compounds in four matrices: metal surfaces, water, soil and transformer oil

The basic principle is to measure the total organic chlorine in a sample and to equate it to an equivalent concentration of the target or expected analyte. The samples are extracted and reacted with a sodium reagent to remove the covalently bound chlorine from the analyte, converting it into inorganic chloride. The resulting chloride is then detected and quantified using a specific chloride ion electrode. The equipment has conversion programs for the main Arochlores and for most of the pesticides and chlorinated solvents

The measurement range is from 3 to 2000 ppm in oils and soils; 10 ppb* and 2000 ppm for water and 3 µg 100cm2 to 2000 µg 100cm2 for wipe test

*ppb: parts per billion

These are “pass/fail” type tests that are based on the release of chlorine in the form of chloride in an aqueous solution. All the reagents are contained in ampoules with the precise amounts to obtain the expected results in fixed concentrations of 20, 50 and 500 ppm.

To eliminate the possibility of false negatives, the kits are calibrated with reference to Arochlor 1242, which is the Arochlor with the lowest chlorine content (42% by weight) found in dielectric oils.

The test time is approximately 5 minutes. If the solution turns purple, the oil contains less PCB concentration than the selected level of the Kit (20, 50, or 500 ppm).

CONSULTATION: Is there a possibility of obtaining false positives? YES, since the samples could contain chlorine from other sources, such as: paints, chlorinated solvents, marine environments, etc.

In any case, the samples with positive results of colorimetric tests should be analyzed in the laboratory by gas chromatography for confirmation and measurement of PCB concentration.

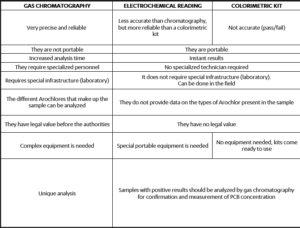

ADVANTAGES AND DISADVANTAGES OF EACH TYPE OF TEST

In Trédi Argentina we recommend the gas chromatographies with electronic capture as precise tests to determine the type of treatment to follow.

In the table we show the main advantages and disadvantages of each type of analysis.