PCBs (polychlorinated biphenyls) were used as dielectric fluids in electrical transformers (1) and capacitors (2) thanks to their excellent physical-chemical properties. In this article, we want to show which are the guidelines that we considered in Trédi Argentina to identify electrical equipment contaminated with PCB.

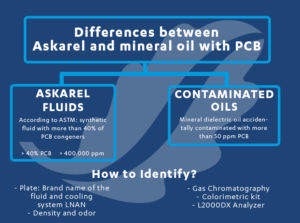

For this purpose, we must differentiate two big groups: the fluids of the “pure Askarel” type and the fluids contaminated with PCB.

Electrical equipment containing “Askarel” fluid was originally designed to work with this type of refrigerant. Their concentrations of PCB congeners exceed 40%, that is, they have more than 400,000 ppm of PCB. We can use three ways to identify them: by the identification plate, by their age, and by the density of the fluid.

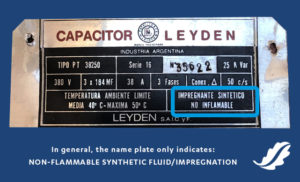

In general, it is easy to identify a transformer or capacitor by analyzing the data on its identification plates:

The insulating liquid is identified by its commercial name: Inerten, Clophen, Pyralène, Arochlor, Apirolio, which are the most common brands found in Latin American transformers.

Other information used by Trédi Argentina to recognize the presence of Askarel is the type of cooling system of the transformer; there are four letters that identify the internal and external cooling system. In the transformers with Askarel fluid, the first letter is an L (3) that means “liquid with flash point (4) not measurable”.

In the case of Askarel-cooled capacitors or condensers, the plate indicates that it contains a NON-INFLAMMABLE synthetic impregnating fluid. It should be remembered that the use of electrical equipment with PCBs was mandatory in some facilities such as mining sites, industrial plants, and hospitals because, in case of fire, they did not burn easily.

The age of the electrical equipment is another way to identify the existence of pure Askarel as a cooling fluid. Transformers and capacitors built before the 80’s have a high possibility of containing Askarel as a dielectric liquid.

This method is only used in Trédi Argentina for a quick determination during PCB exports. The relative density of Askarel fluids is from 1.3 to 1.54 (being water=1), therefore they are heavier than water. With the appropriate personal protection equipment, a sample of Askarel is taken with a disposable pipette and poured into a test tube with water. The drops of Askarel will be deposited at the bottom of the tube by its density. At Trédi Argentina we do not recommend it as a method of identification of Askarel.

Can I send a sample of Askarel to a laboratory for gas chromatography?

Yes, but I must inform the laboratory that the fluid is a probable Askarel. In this way the laboratory will take all the precautions to dilute the sample properly to inject it into the chromatograph to avoid contamination of the columns of the equipment.

Due to accidental contamination during electrical maintenance work, we can find transformers with dielectric mineral oil or silicon contaminated with PCB. This process is called “cross-contamination”. Cross-contamination is produced either by direct contact or by the use of accessories and elements of equipment with PCB, thus transferring the contaminant to the dielectric oil.

In this case, we have no way to identify a PCB-contaminated transformer by its plate or age; the only way is through oil analysis. There are different methods of analysis on the market, the most precise being gas chromatography with electronic capture (GC-ECD). Colorimetric kits can be used for rapid determinations as well as equipment that calculate the concentration of PCB in the sample through the electrochemical detection and measurement of chloride ion concentration.

We recommend the following reading:

Cross-contamination:

PCB handling procedure during equipment maintenance. Mario Cesar Mendoza Zegarra / Ministry of the Environment, General Directorate of Environmental Quality – Lima: MINAM, 2016. Basel Regional Center for South America GEF/UNEP CRBAS Project “Best Practices for PCB Management in the South American Mining Sector” Buenos Aires, Argentina